www.kingbopharmatech.com

♦ High Quality Raw Material Supply Solutions

♦ Process synthesis development

♦ Chemical Synthesis Solutions

♦ Fermentation & Enzymatic Solutions

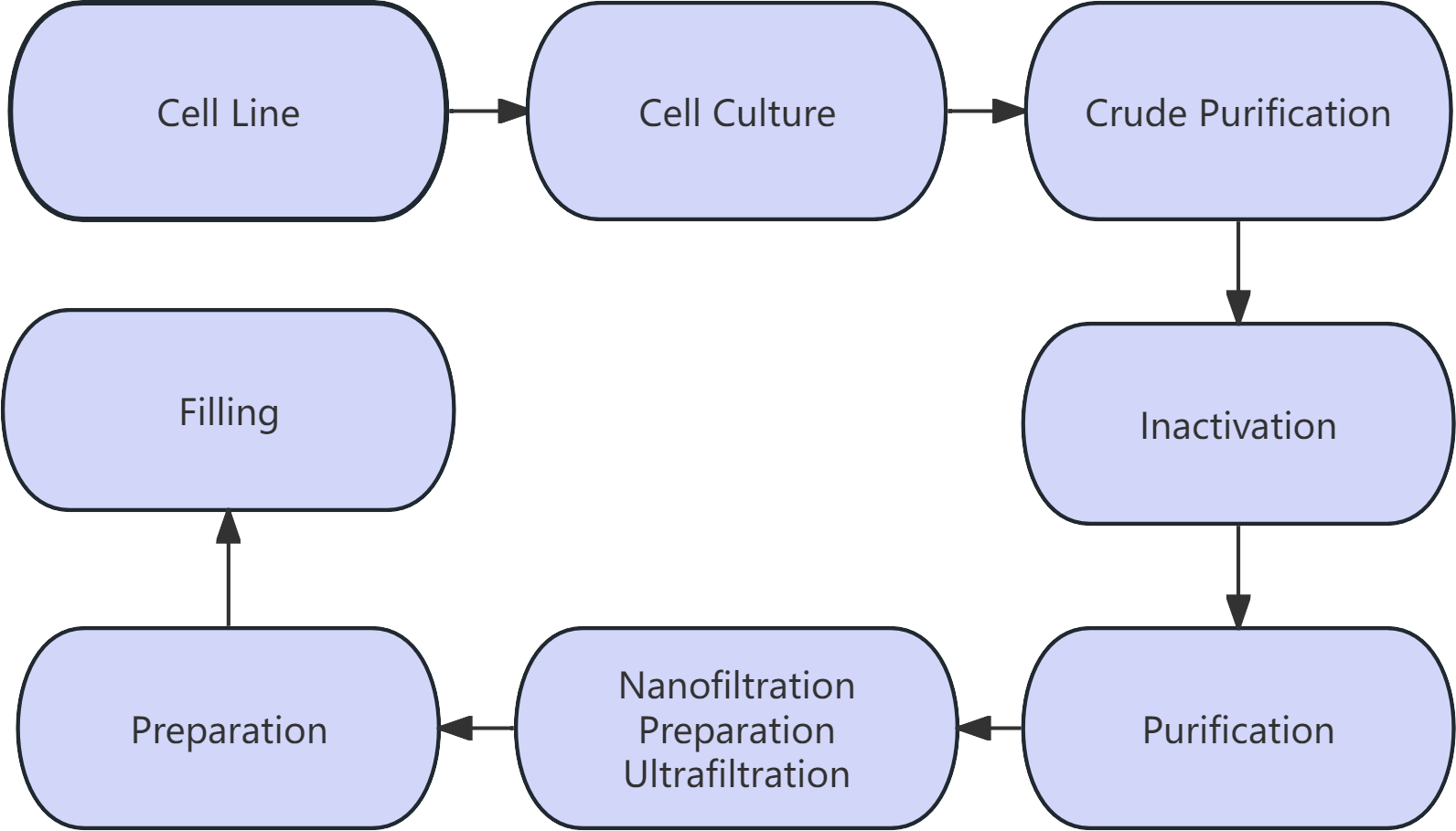

♦ Bio-pharmaceutical Solutions

♦ KNOW-HOW Service Solutions

♦ High Quality Raw Material Supply Solutions

♦ Process synthesis development

♦ Chemical Synthesis Solutions

♦ Fermentation & Enzymatic Solutions

♦ Bio-pharmaceutical Solutions

♦ KNOW-HOW Service Solutions

Route design and optimization:

Reaction mechanism study (thermodynamic/kinetic analysis);

Alternative route screening (economic, environmental, safety);

Catalyst/solvent selection (activity, recovery utilization)

Process parameter control:

Temperature, pressure, pH, reaction time optimization;

By-product inhibition and transformation strategies;

Continuous flow chemistry vs. batch production;

Scale-up production verification:

Process stability testing from laboratory to Pilot Plant;

Correlation analysis of key quality attributes (CQAs) and key process parameters (CPPs)

Solutions we can provide:

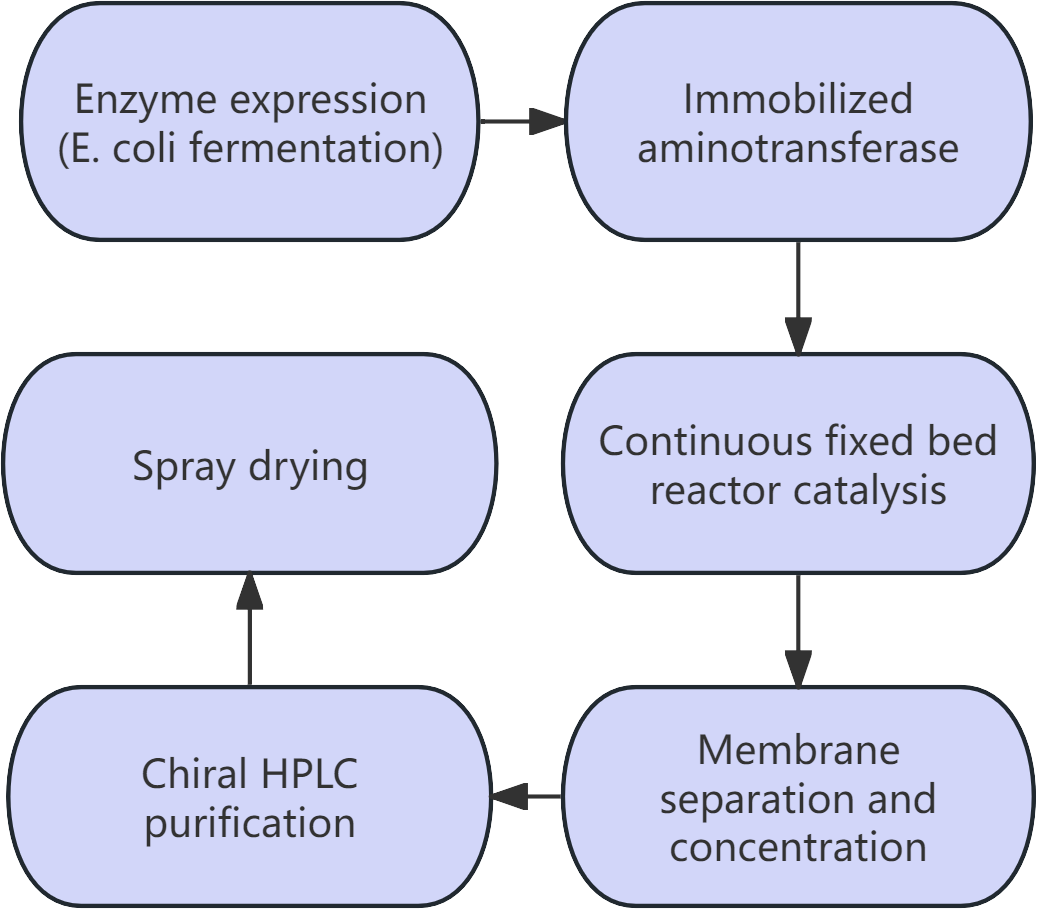

1.Fermentation process development

2.Plant design and environmental control

3.Fermentation equipment selection and configuration

4.Pollution control and biosafety

5.Quality control and analysis

6.Regulations and compliance

7.Economy and cost control

Key equipment:

Fermenter → centrifuge → immobilized reactor → nanofiltration system → chiral column → spray drying tower

Plant design and infrastructure

1. Functional area planning:

Physical isolation of synthesis area, purification area, storage area and quality inspection laboratory;

Explosion-proof area division (for flammable and explosive chemicals)

2. Engineering system configuration:

Ventilation and waste gas treatment (local exhaust hood, activated carbon adsorption);

Wastewater treatment systems (neutralization, precipitation, biodegradation);

Automation Control (DCS/SCADA system integration)

3. Safety design:

Anti-leakage facilities (secondary cofferdam, emergency collection pool);

Fire fighting system (gas extinguishing, spraying device);

Emergency shutdown (ESD) and safety interlocking mechanism

Core reaction equipment

Reactor material selection (glass lining, Hastelloy and other corrosion resistant materials)

Microchannel reactor (for high exothermic/hazardous reactions)

Separation and purification equipment (Creation)

Centrifuge, membrane filtration system, chromatographic column

Mold design (temperature control, stirring rate optimization)

1.7.1 Stainless Steel Bioreactor—Capacity up to 20000L

♦ Online CIP/SIP;PH control accuracy ±0.01, resolution is 0.01;

♦ DO control accuracy ±2%, resolution is 0.1%;

♦ The temperature control accuracy ±0.1°C, and the display accuracy is 0.1°C;

♦ Electronic signature, electronic record and audit trail functions;

♦ Two forms: surface aeration and deep aeration;

♦ Auxiliary adjustment, and the steady-state accuracy is ±0.2%;

♦ The specific configurations can be customized according to the needs of customers.

♦ It’s suitable for industrial-scale purification, pilot scale-up and industrial production;

♦ The supporting software is easy to operate, and the data can be traced to meet the requirements of audit trails;

♦ Reasonable design, compact structure, small dead volume, small footprint and no dead angle in the pipeline;

♦ Key components such as pumps, mixers, detectors and valves are all imported, with accurate data and stable performance;

♦ The specific configuration can be customized.

♦ Hygienic design meets the GMP requirements;

♦ Glass chromatography column tube can achieve efficient and repeatable filling;

♦ Simple operation, convenient use and easy maintenance;

♦ All materials meet the requirements of biopharmaceutical production.

♦ Automatic chromatography column filling;

♦ The excellent design of distributor can realize linear amplification;

♦ Fast start-up, reproducible results, and long stable run times.

♦ Strictly comply with JB/T4735-1997 or GB150 and GMP standards;

♦ Online CIP/SIP & Hygienic design;

♦ Appropriate diameter-to-height ratio design, customize the mixing device as needed;

♦ Automatic control system helps to reduce labor intensity;

♦ Humanized structural design-easy operation, stable transmission and low noise.

We focus on biopharmaceutical KNOW-HOW services, covering the whole chain of technology empowerment from research and development to industrialization.

♦ 1.Technology transfer and application: Help customers quickly master cutting-edge technologies and improve productivity.

♦ 2.Process optimization and improvement: evaluate all aspects of the production process, find out the key factors affecting efficiency, quality and cost, and propose targeted optimization programs.

♦ 3.Problem diagnosis and solution: When customers face technical problems and production bottlenecks, we will find the root cause of the problem and develop solutions through field research, data collection and analysis.

♦ 4.Training and ability improvement: According to the needs of enterprises, tailored training courses covering theoretical knowledge and practical operation.

♦ 5.Strategic Planning and Consulting: Providing strategic planning and decision-making consulting services based on a deep understanding of industry trends, market dynamics and technological developments.